Cleaning equipment and its importance in the control of Listeria in food production

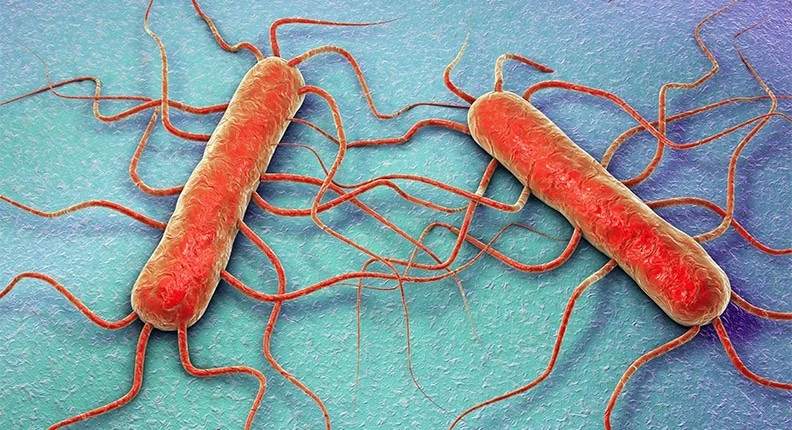

Listeria monocytogenes is a bacterium which can give rise to food poisoning and so is a serious food safety concern in food production.

In 2015 according to Public Health England, there were 169 cases of listeriosis in England and Wales. This might not sound many, but the mortality rate for this pathogen is high at approximately 30% of cases.

The elderly and unborn / newly-born babies are most vulnerable to the disease. Listeria monocytogenes is the only member of the genus Listeria which is recognised as a human food pathogen. However, all Listeria species have the same growth requirements, and so the presence of a ‘non-hazardous’ Listeria can be indicative of the presence of Listeria monocytogenes.

Listeria is found in the general environment and so can be associated with any food that is grown in association with the soil (e.g. salad leaves). This bacterium can:

- Grow - albeit slowly - at chill temperatures and is especially a concern for chilled ready-to-eat (RTE) foods.

- Inhabit and persist in the food production environment. It thrives in conditions where there is plenty of water

- Produce protective mechanisms (for example ‘biofilms’) to help it survive.

These characteristics enable Listeria and Listeria monocytogenes to cross-contaminate foods that have undergone a process to eradicate vegetative pathogens (e.g. cooking), and so it can pose challenges to food manufacturers.

Â

Where to look for Listeria

When monitoring for the presence of Listeria in a food production facility there are key areas to look at. Two of the most frequently contaminated are:Â

- Drains are the prime place to look for this bacterium, because each time the production area is cleaned, residue leaves via the drains.

- A close second on the list of places to look is ‘cleaning equipment’ such as brushes and squeegees, which are used as part of any clean-down process. Most, if not all, cleaning equipment will be used as part of routine cleaning.

Cleaning equipment - preventing cross contamination

Cleaning equipment is often forgotten when considering how to maintain a Listeria-free production environment.Â

- Cleaning equipment should itself be cleaned after each use to prevent it being a potential route for cross contamination.Â

- Storing cleaning equipment such as squeegees in a sanitiser bath when they are not in use will help to reduce cross contamination. This does require the sanitiser solution to be remade on a very regular basis, as the presence of organic material on the cleaning equipment can neutralise the sanitising agent.

- Cleaning equipment should be stored or hung up when not in use. If equipment is left on surfaces such as the floor, it can remain wet and can support growth of any Listeria cells present.

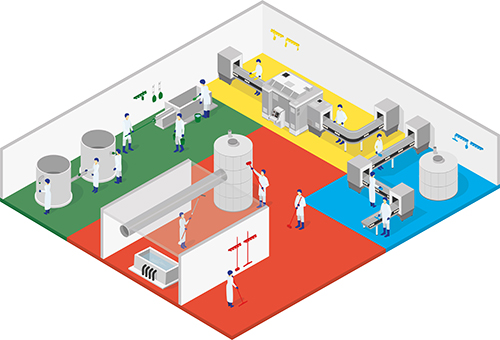

- Colour coding of cleaning equipment is frequently used to ensure that dedicated cleaning equipment is used only where it is supposed to be. Segregation can be by area of the production facility, as well as ‘zone’. For example, cleaning equipment used for product-contact surfaces are often separated from floor-contact cleaning equipment by colour code.

- When cleaning equipment becomes worn out, it can readily harbour bacteria such as Listeria. Consequently, it should be replaced regularly.

The Food & Drug Administration (FDA) has recently identified four zones of importance when controlling Listeria in RTE production facilities in the USA.

These of course are also of relevance to UK and EU operations:

Zone 1 Direct food contact surfaces in the plant (e.g. blenders, conveyors)

Zone 2 Non-food contact areas in the plant that are closely adjacent to product contact surfaces (e.g. framework of equipment, drip shields)

Zone 3 Non-food contact surfaces that are not close to food contact surfaces zone 1 (e.g. walls, drains) and zone 4) areas

Zone 4 Areas remote from the product processing areas (e.g. office areas, locker room)

Read more

Listeria monocytogenes is a very dangerous food borne pathogen. The 2017/2018 outbreak in South Africa, where there have been approximately 950 cases and 180 deaths is testament to that. While producers of ‘at risk’ products should be aware of problems associated with Listeria and better prepared with a knowledge of control measures, plant managers need to pass this information to their entire staff. With the right training and the proper controls, staff should understand how to identify Listeria problem areas, reduce the risk of listeriosis with hygiene practices, and control future outbreaks.

Â

Recent blog posts

Listeria, its most common hideouts, and where to clean

If you produce chilled, ready-to-eat foods, you’ll need to know where you have to clean to avoid food contamination. This post details the most common Listeria hideouts – and how to clean for this...

Maximize Global Food Safety Scheme compliance

Find out what Global Food Safety Schemes, including BRC, FSSC 22000, and SQF, say about cleaning tool selection, use and maintenance requirements, and how you can optimise your cleaning tool audit...

Benefit from the full Vikan experience with a Vikan site survey

Today, the best way to make your investment in Vikan profitable is to have a customised site survey carried out. In sectors with high hygiene requirements, such as food preparation environments...

Face-to-face Table Lifting Frame

A face to face desk stand is a desk design that usually consists of two tables and a middle stand so that two people can sit on either side of the table and work face to face. This design helps promote teamwork and communication, as two people can easily exchange ideas and discuss issues. Face to face table racks also save space because two people can share a table instead of needing two separate tables. In addition, face to face desk racks can also improve the efficiency of the office, as it can reduce the time for communication and coordination, making the team closer and more efficient.

Face-To-Face Table Lifting Frame,Face To Face Work Table Stand,Mobile Lifting Table,Smart Lifting Desk

Suzhou Herstar Medical Technology Co., Ltd. , https://www.hosunherstar.com